I'm really not doing well with keeping this blog up to date! Which is going to make this update a bit full.

But first things first. The heater tray was fully welded in, cleaned up and then etch primed. The lower flanges were spot welded from within the foot wells and then cleaned back to hide the welds. The top plate will will be done when I'm ready to get that far. But I'm happy with how this all looks for now and it still allows the engine to fit easily. Or as easily as a 2.5l V6 will in a Sprite!

The next step was to get cracking with the rear suspension and get more done on the back end before moving on to the front. So the first thing to do was to actually finish the transmission tunnel off and get the plates fitted to the rear bulkhead face to help strengthen the diff mounts.

I've not got a photo showing all four plates welded as yet, as the bits over the top of the upper mounts hasn't been done. I tried doing one of them, but the very restricted access makes it virtually impossible to see what I'm doing, so those bits can wait until I next roll the shell over.

But with the plates as in as they can be for now, I had a look at the suspension itself and the brakes. This first meant getting the coil overs hanging in place so that the linkages would all hang under their own weight. So I made a set of top brackets for the coil overs and got them bolted in place, only to realise that the lower mounts on the coil overs, which I hadn't really looked at before, take a 10mm bolt whilst the De-Dion tube takes a 1/2" bolt. But as a temporary fix, I've removed the misalignment washers so I can at least clamp a 1/2" bolt in place for now. The thread lengths are different on the top mounts so I can fit them more easily as I have to do it with one hand feeding the coil over in from below whilst trying to put a washer and nut on from above. This was I can locate them one thread at a time.

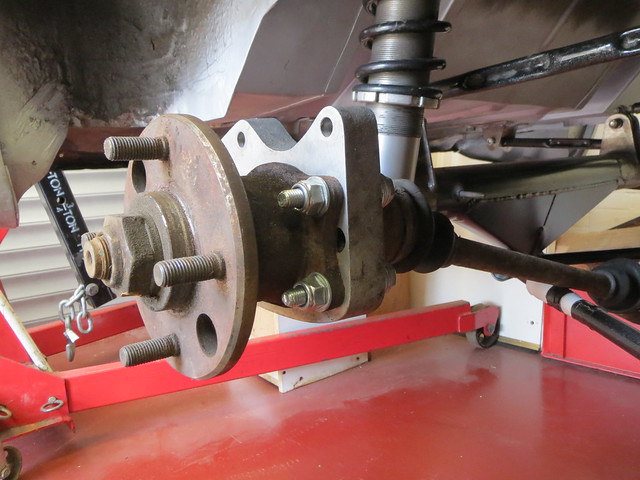

With that done, the rear suspension was now intact at last, and I could get the hubs in place.Only it very quickly became apparent that the disc brake drive shafts and hubs that I have don't fit the De-Dion ears that I got hold of! Arse. I know this isn't a problem with the ears, as the design of them hasn't changed. So following yet more research, it turns out that I should have used the smaller drum brake hubs and drive shafts. So back to Ebay it was!

And once I found a set of shafts and hubs, I could actually get the hubs bolted in place and the callipers on the ears too. Only to find that the brake discs I had been planning on using are too big. Thankfully, this isn't a big problem as the right discs are only £25 or so each, even from Caterham! I can still use the discs I have to measure up for where the wheels fit and what not as they still move the wheel outwards by the same amount.

This photo shows the difference between the two types of set ups. The main difference is the width of the CV joint. The drum brake tripod joint is much slimmer. This also means it's lighter, which is a good thing.

And whilst I know they won't fit, as the tyres are too wide for the arches, I couldn't resist trying a wheel on for size. I quite like the way it looks! Just need to see how much surgery is required to make a square wheel arch shell accept a 185 section tyre.

So following the sense of achievement that seeing a wheel on the car for the first time if four and a half years gave me, I had to spend far more time than I wanted to carefully measuring clearances so I could make a start on fitting the diff. But as that's quite involved, I'll put that into it's own update.

No comments:

Post a Comment