From where I left off with the frame, I got the second side cut and tacked into place. I then decided to cut the entire side out and weld it on the bench. This means I can do all the welding the right way up, but it does mean a bigger hole in the bulkhead so I can fit the diff mount end of the frame in.

Before it was welded in, I fitted two of the lower frame tubes before access became awkward round the frame. The rear most tube should be hard up against the bulkhead, but I decided that the work needed to do this wasn't worth the effort. So the tube sits roughly 1" forward of where it should be.

The only bit of the frame I could safely fit for now was the rear top tube, against the bulkhead. The welding needs tidying up as yet, as I had the bulkhead hole to fill in slightly.

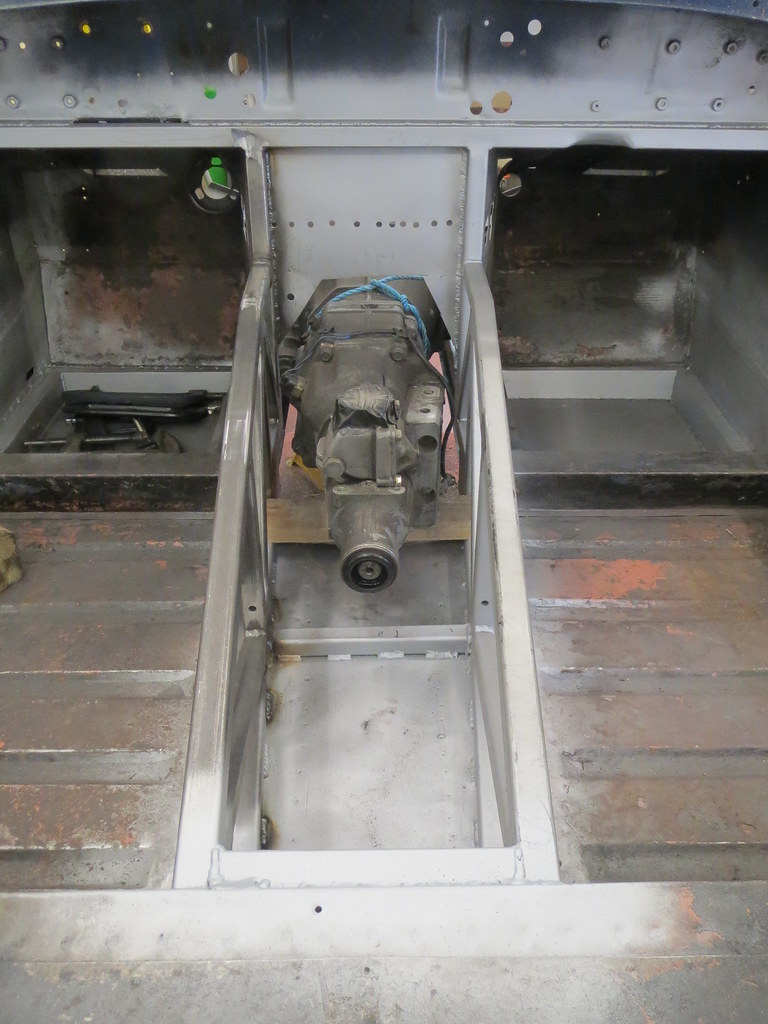

The rest of the frame tubes had to wait until the engine and box went in, as I knew some may sit in the same place as the box. However, before I could fit the engine and box, I needed to close off the footwell tops and the chassis rail notch.

I've left the small infill piece out of the RHS footwell for now as it might come in handy for running cables for the ECU, since it's so close to the engine.

The chassis notch took a bit more time to do, as I had to form an odd shaped box:

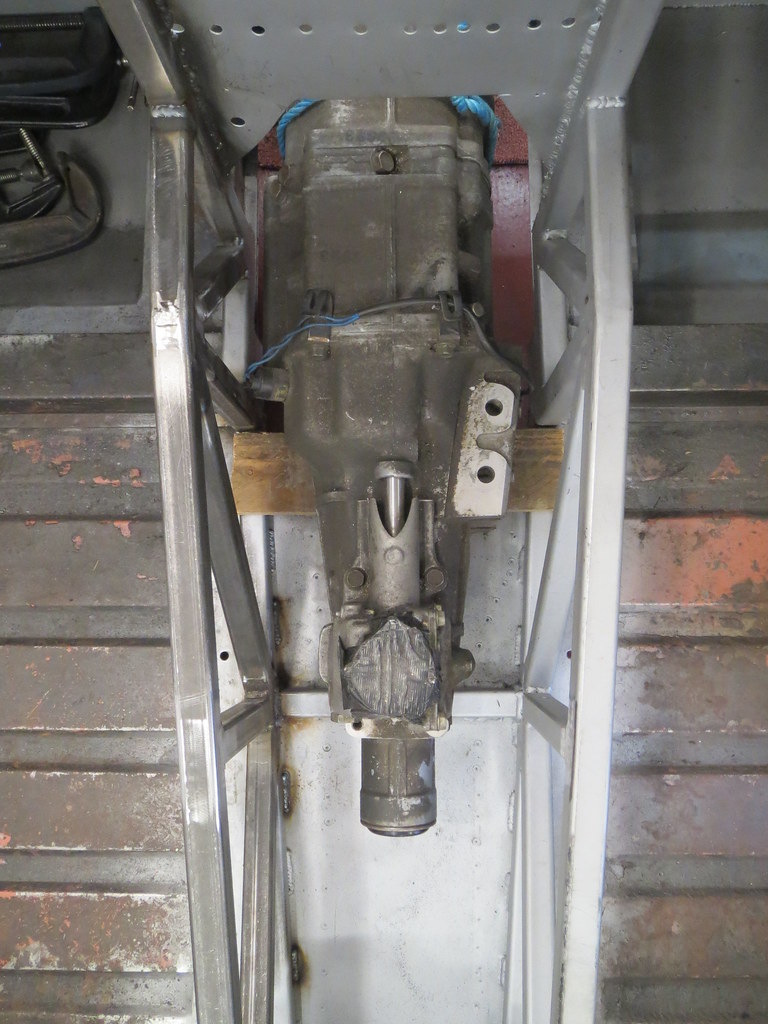

And so I could get the engine and box back out from under my bench and into the shell. Thankfully, there's loads of room round the gearbox. I haven't checked the heads yet, as that can wait for a quiet evening to do.

It's just as well that I decided not to fit the other cross tubes, as the next one forward would only just miss the gear turret. The other would fit above the box though. I also have space to partly replace the chassis cross member with a lower version, which is good news.

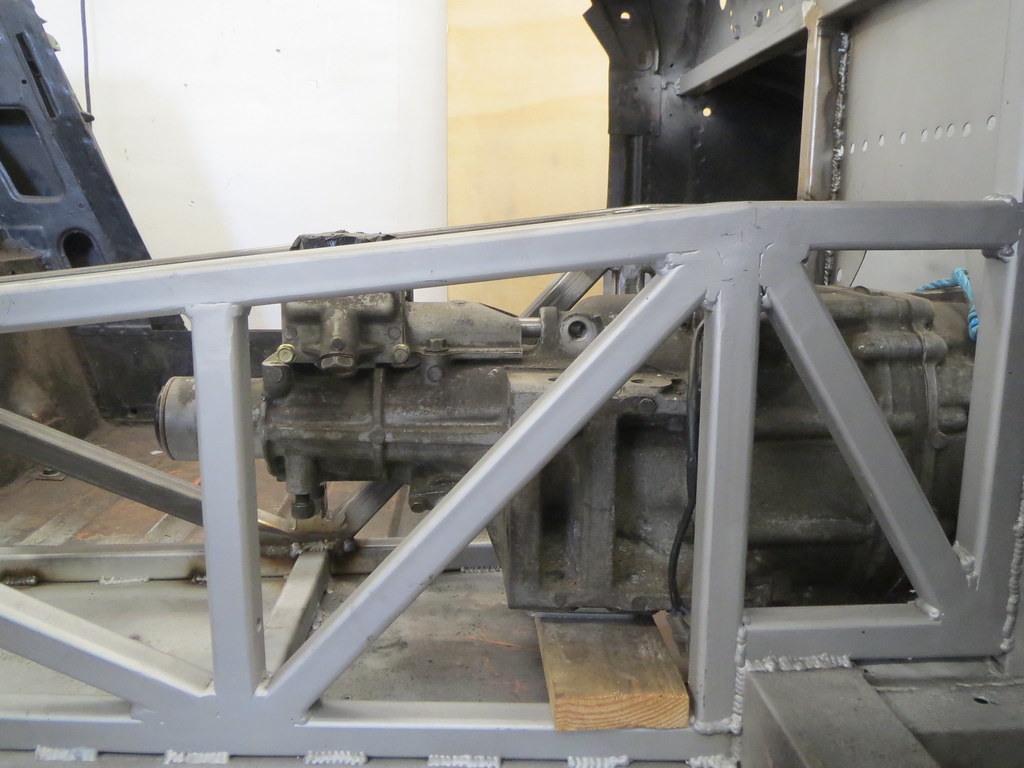

The next thing to do was the gearbox mount. This is a Mk1 go at it, as I'm not sure if this is the best way or not yet. I'd like to be able to screw the bobbins straight to the box, but I can't find any with an M10 x 1.0mm thread.

The frame bracket is formed from a strip of 2mm sheet bent round an off cut to give a good fit. I ran out of time to start cutting the tube back to suit, so that's the next thing to do before making a matching version for the other side. I may link the two halves together yet to make it stiffer, but I'm not sure. I'll wait until both sides are done and then see if I can move the box about at all.