I'm not doing a brilliant job of keeping this blog up to date, but I am making progress.

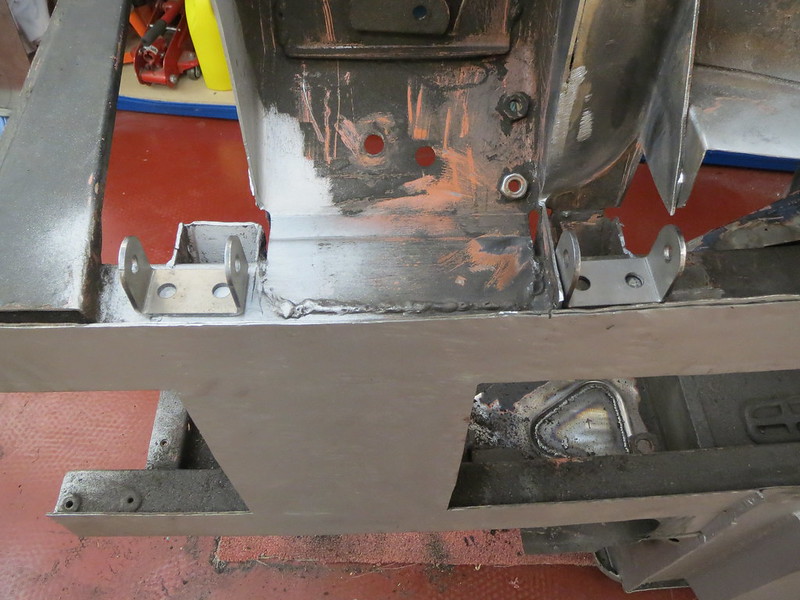

Now I had a base for the tunnel frame, I could make a start on the rest of the rails for this side. The bottom rail was trial fitted before having it's closing piece fitted to the rear end. This will close the tube off and also give any diff cradle something to bolt to.

With that in place, the next section along could be made up and welded in place.

The top rail was next. I was in two minds over if I should make this rail from round or square tube. Round would give a nicer edge/curve to the top panel, but square is easier. I also have square tube, and the only round I have is expensive CDS, which I will be using for the wishbones. So square won out in the end.

That's it for now, as that took a while to get right although the top rail is fully welded in the cabin. I can't rush this bit, as once the rails are in, cutting them out will be quite a task. The next steps are the two remaining vertical tubes, and then the cross braces.

Following on from a few projects that have been scattered to the winds on various websites, I thought it might be about time I put all the various bits and bobs I do in one place. Welcome the The Workshop.

Search This Blog

Monday, 19 May 2014

Saturday, 10 May 2014

Busy, busy, busy.

I've been rather busy over the past three days!

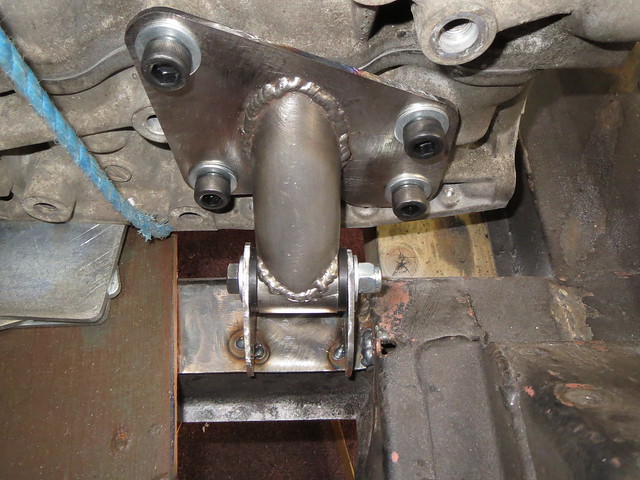

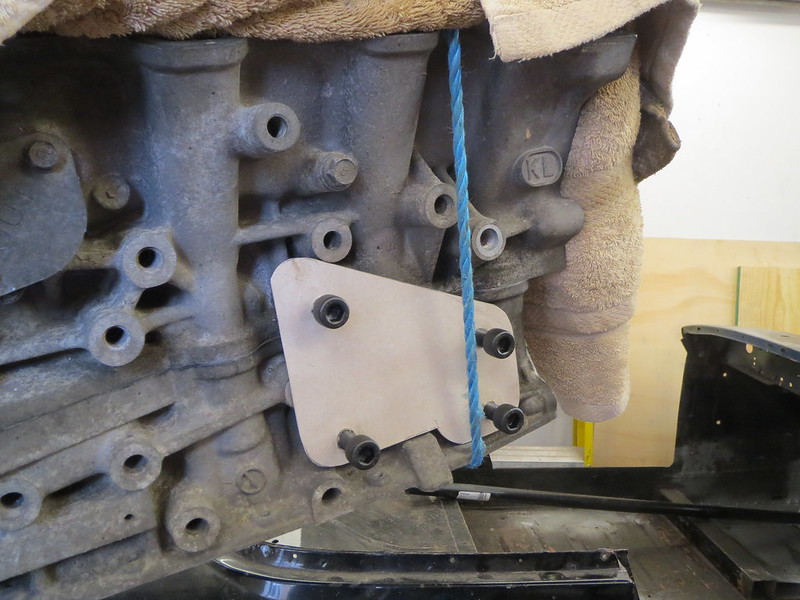

The engine mounting plates were cut out and the chassis tabs bolted to the bush tubes for trial fitting.

And then the joining tube, 38MM CDS was cut and shaped. Everything was lined up and then welded together.

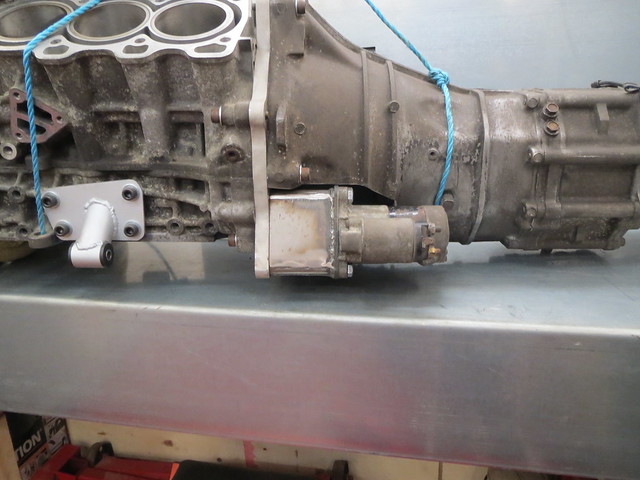

With the mounts done, and the engine sitting square in the shell, it was time to fit the starter motor to the gearbox. The MX-5 box I'm using doesn't have a space for a starter, so I've had to make one.

With the starter now bolted into place, I could get the engine back in the shell and start lining up for making enough clearance space for the cylinder heads and the starter.

The starter needs a hole in the side panel, and a notch in the chassis rail.

And then both footwell tops were alter to clear the back of each head.

None of these bits have been welded up yet, in case I change my mind at some point about the amount of space I want. I doubt I will, but you never know.

So that was the engine side of things sorted for now, and it was on with the next step: the new transmission tunnel. There were the remains of the old tunnel to remove first so that I could start measuring up for the new design.

The first step was to fit a cross beam to the dash panel

And then I could get on with fitting the other tubes. I didn't get far before I ran out of time, but I now have a solid base from which to work.

The engine mounting plates were cut out and the chassis tabs bolted to the bush tubes for trial fitting.

And then the joining tube, 38MM CDS was cut and shaped. Everything was lined up and then welded together.

With the mounts done, and the engine sitting square in the shell, it was time to fit the starter motor to the gearbox. The MX-5 box I'm using doesn't have a space for a starter, so I've had to make one.

With the starter now bolted into place, I could get the engine back in the shell and start lining up for making enough clearance space for the cylinder heads and the starter.

The starter needs a hole in the side panel, and a notch in the chassis rail.

And then both footwell tops were alter to clear the back of each head.

None of these bits have been welded up yet, in case I change my mind at some point about the amount of space I want. I doubt I will, but you never know.

So that was the engine side of things sorted for now, and it was on with the next step: the new transmission tunnel. There were the remains of the old tunnel to remove first so that I could start measuring up for the new design.

The first step was to fit a cross beam to the dash panel

And then I could get on with fitting the other tubes. I didn't get far before I ran out of time, but I now have a solid base from which to work.

Wednesday, 7 May 2014

Looks like a car again......

Rather than go through and explain what I've been up to, I'm just going to list everything I've done and all the photos I've taken in the last three weeks. Typing it all out would take ages!

The splash panel has been cut back and hammered flat(er). Since it's not a structural panel, I'm not bothered about the loss of the folded section.

The front suspension mounts are cleaned back and ready for the next stage. The brackets are just sat in place so I could get a feel for what things will look like.

The end I can get to for the cross member has been capped off.

A wonky patch on the passenger footwell has been replaced. I've no idea why I left this in place previously!

I've made a start on closing in the front panels to help stiffen the front end. The other two triangles will be done when the cars the right way up.

The remains of the heater tray have been cut out at last, and the area cleaned of paint and underseal. There will be a new tray going in once the engine's on it's mounts.

The shell was now the right way up again and looking something like a car too. So I've moved on with getting the engine mounted.

There's not a lot of room around the engine once I mocked up the steering column! Somehow I've got to fit 3-1 manifolds, the steering column and an alternator in there somewhere!!

So the next thing to do was to start on the front engine mounts. The gearbox mount will be done next. The front rails were strengthened with 2mm thick plates to help take the weight and to add a little more to the general strength of the shell.

I only got as far as making card templates for the engine side of the mounts, so that's what I'll be starting with today. The chassis side of the mounts will be 3mm plates welded to the new rail plates. This way the mounts are kept small, and with a hard plastic bush in them. They're the same things as I intend to use on the suspension, so if I find the mounts too hard, or that they transfer too much vibration I can get softer ones without having to alter anything else.

The splash panel has been cut back and hammered flat(er). Since it's not a structural panel, I'm not bothered about the loss of the folded section.

The front suspension mounts are cleaned back and ready for the next stage. The brackets are just sat in place so I could get a feel for what things will look like.

The end I can get to for the cross member has been capped off.

A wonky patch on the passenger footwell has been replaced. I've no idea why I left this in place previously!

I've made a start on closing in the front panels to help stiffen the front end. The other two triangles will be done when the cars the right way up.

The remains of the heater tray have been cut out at last, and the area cleaned of paint and underseal. There will be a new tray going in once the engine's on it's mounts.

The shell was now the right way up again and looking something like a car too. So I've moved on with getting the engine mounted.

There's not a lot of room around the engine once I mocked up the steering column! Somehow I've got to fit 3-1 manifolds, the steering column and an alternator in there somewhere!!

So the next thing to do was to start on the front engine mounts. The gearbox mount will be done next. The front rails were strengthened with 2mm thick plates to help take the weight and to add a little more to the general strength of the shell.

I only got as far as making card templates for the engine side of the mounts, so that's what I'll be starting with today. The chassis side of the mounts will be 3mm plates welded to the new rail plates. This way the mounts are kept small, and with a hard plastic bush in them. They're the same things as I intend to use on the suspension, so if I find the mounts too hard, or that they transfer too much vibration I can get softer ones without having to alter anything else.

Subscribe to:

Comments (Atom)